Flow computer

- Up to 2 independent installations (A, B )

- Flows and energy balance calculations (systems X )

- 10 measurement inputs

- Math channels & functions (+, -, /, *, √)

- Alarm & control functions, 4 solid state relays (SSR)

- 4-20mA analogue output – one or two (option)

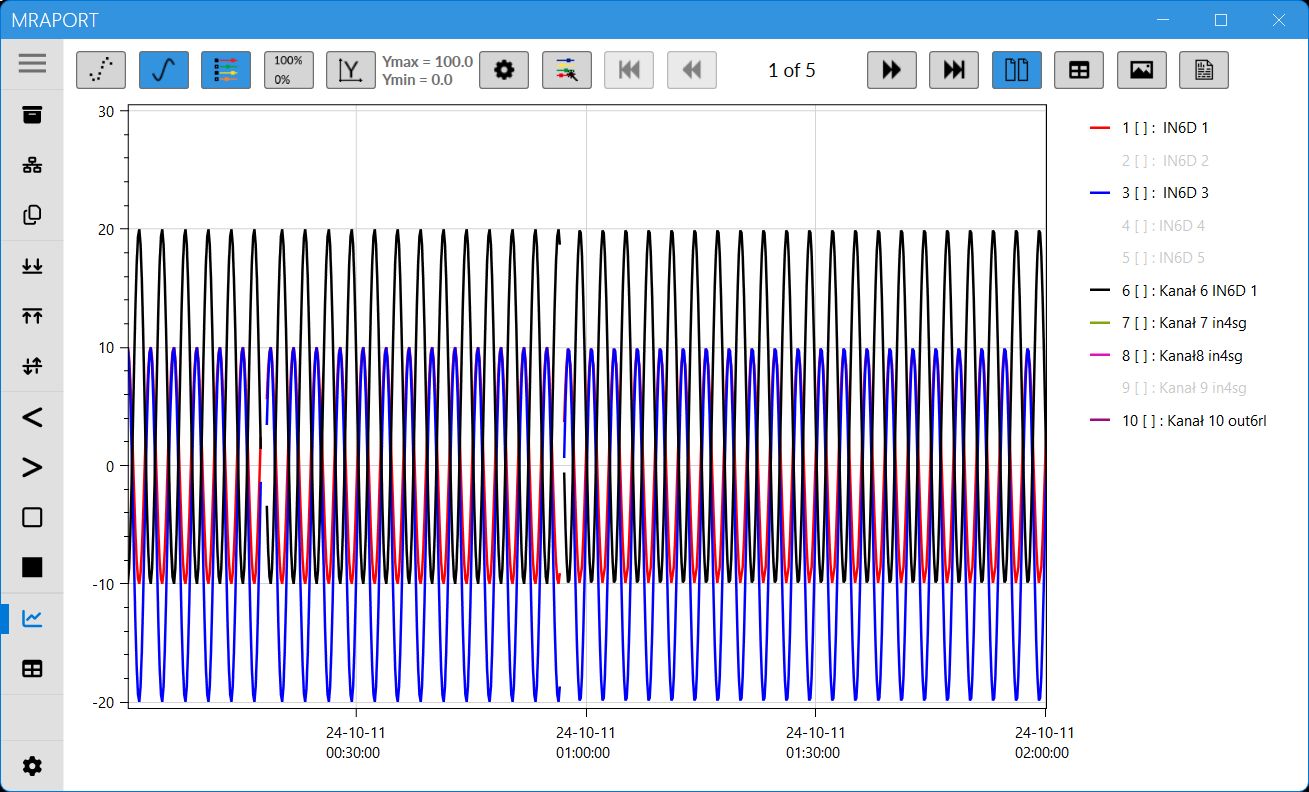

- Advanced data logging, recording data to the text files, 2 GB internal data memory

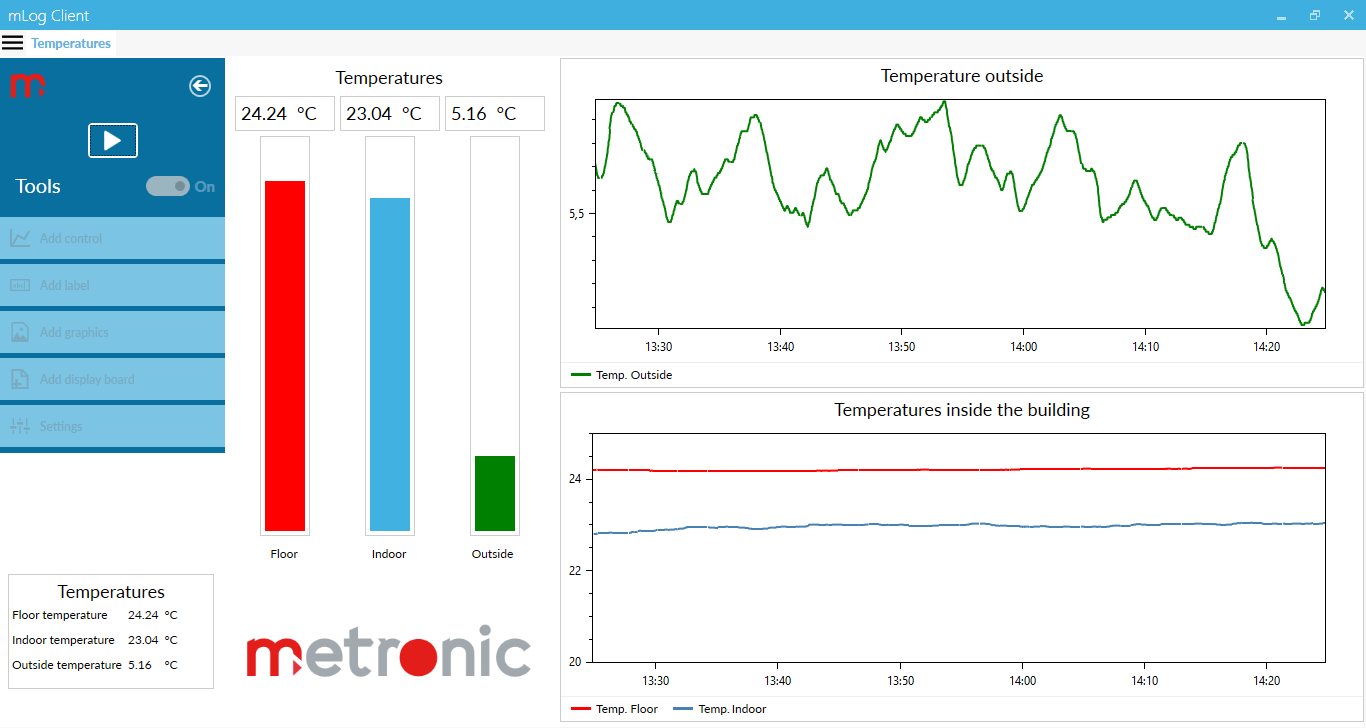

- User configurable data presentation, the colour TFT display

- RS-485 port (Modbus RTU)

- Ethernet port (Modbus TCP, www server)

- USB port on the front panel

- GSM module (option)

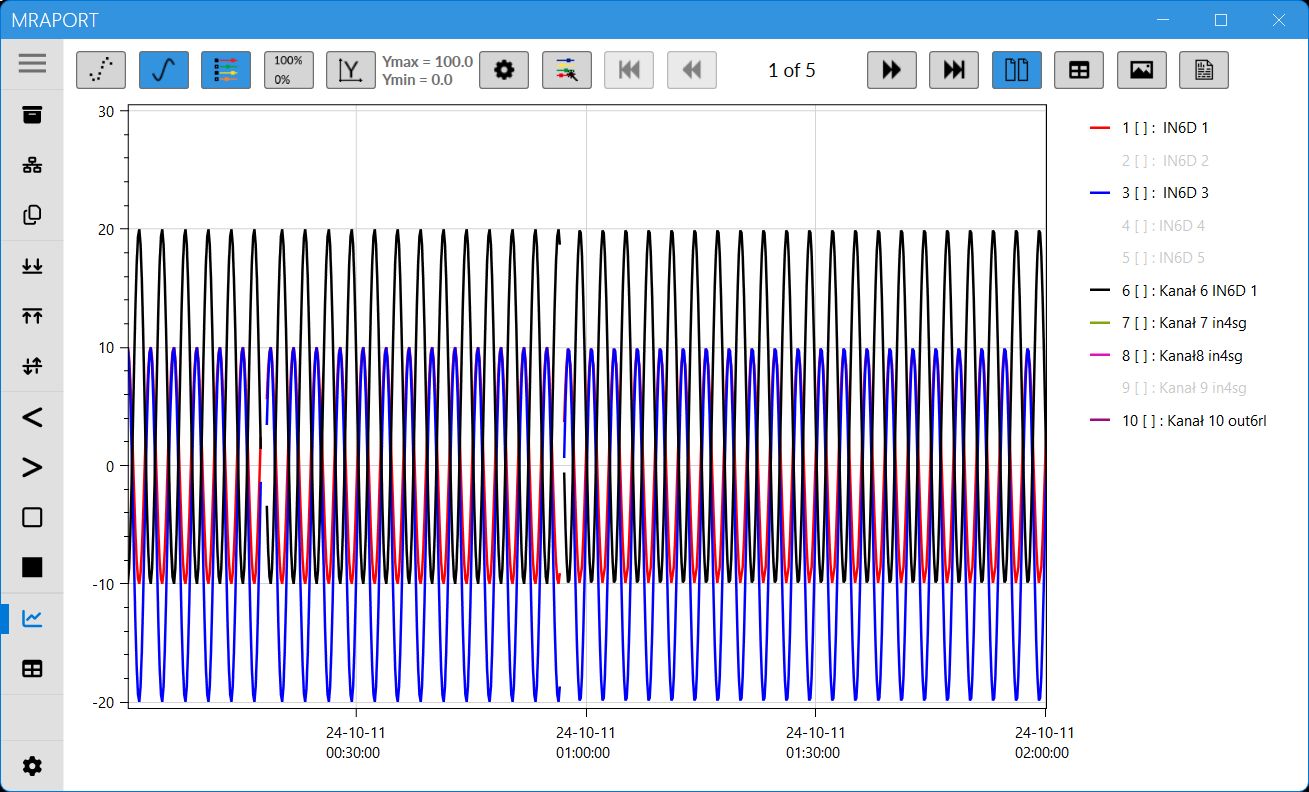

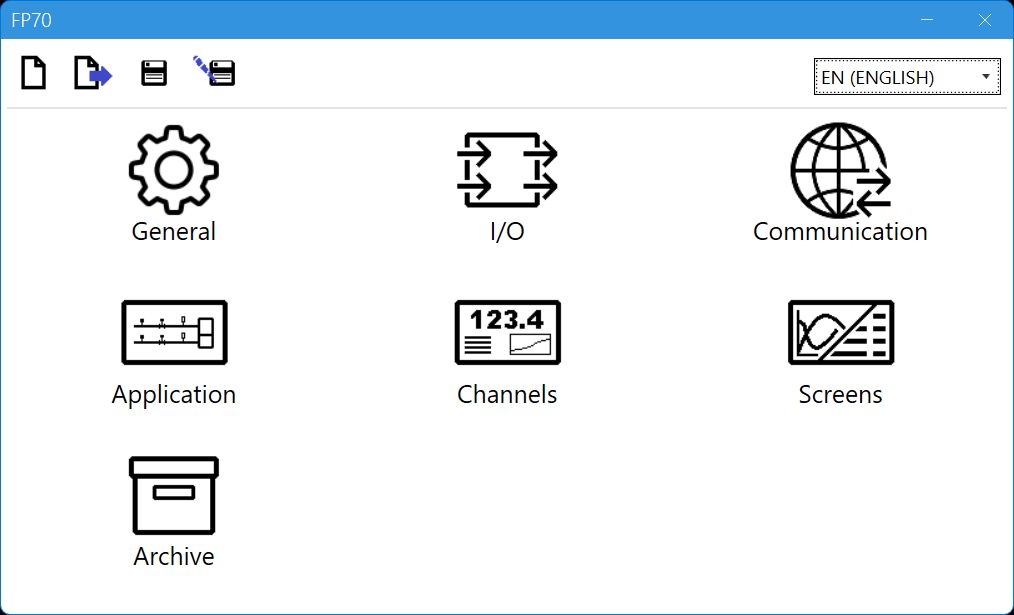

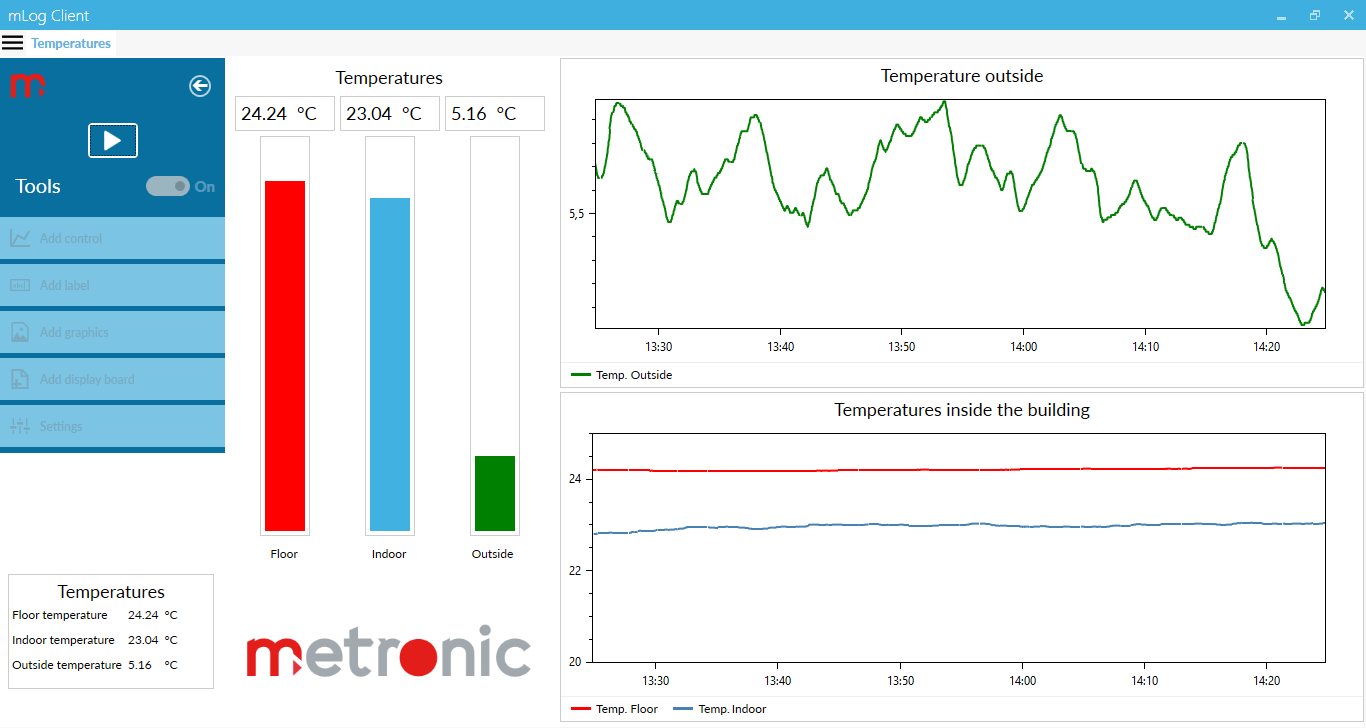

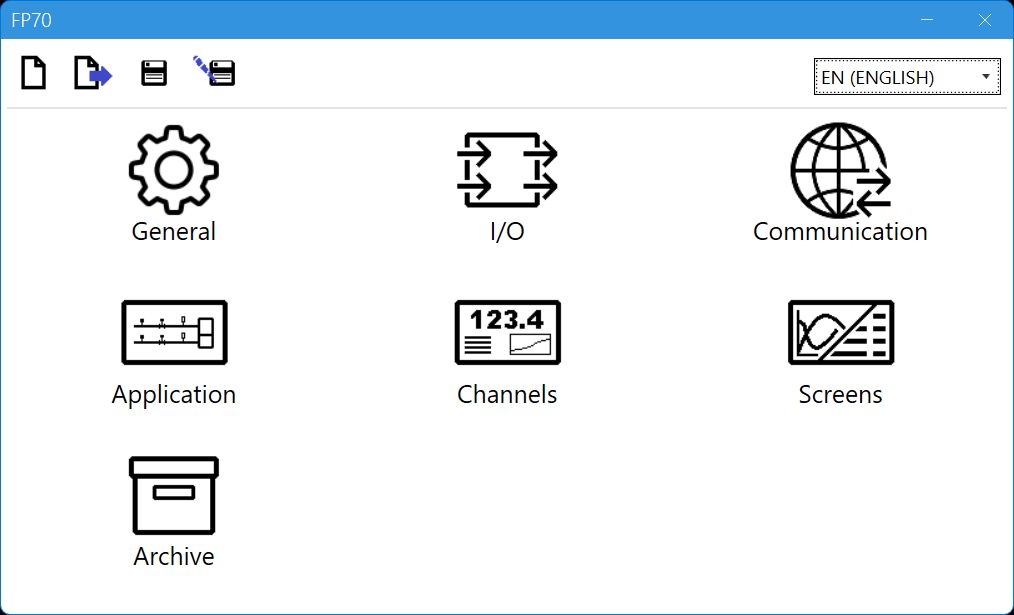

- Dedicated PC software for commissioning and archive data visualization

- Available languages: EN, DE, ES, FR, IT, PL, PT

Applications for steam, liquids and technical gases

- For A, B main application setup one of possible applications using a configuration wizard:

- the flow and heat of a liquid medium

- the flow and delta heat of a liquid medium in a closed supply-return installation

- the flow and delta heat of a liquid medium in an installation with different supply and return flow rates

- the flow and heat of a steam

- the flow and heat of steam for steam-condensate conditions

- the flow and delta heat in a closed steam-condensate installation

- the flow and delta heat in a steam-condensate installation with different steam and condensate flow rates

- the flow and delta heat in a steam-generating installation with the supplied water flow rate measured

- the flow and heat of a technical gases

Flow rate measurement

- The flow computer can work with:

- mass flowmeters

- volume flowmeters

- differential pressure devices with approximation by square root curve or differential pressure devices (orifices and nozzles) according to iteration algorithm according to

PN-EN ISO 5167 standard (only for water and steam)

Inputs and channels types

FP70P/FP70W has: 10 analogue inputs, Ethernet port and RS-485 port. In addition, 24 auxiliary channels are available, which can be used as measuring channels or as a math channels. The device enables supplying the current loop for 4-20mA transducers. Up to 10 User’s characteristics can be defined.

- 2 x RTD, two inputs adapted for connection of resistance temperature sensors (Pt100, Pt200, Pt500, Pt1000, Ni100, Ni120, Ni1000, Cu50, Cu53, Cu100, KTY81, KTY83, KTY84)

- 6 x I, six inputs for interaction with 0/4-20mA transducers only,

-

2 x PULS, two inputs intended for connection of transducers with a pulse output (range 0.02 Hz … 12,5 kHz).

Auxiliary channel

- 24 auxiliary channels, measurement of additional quantities or calculation of the formula entered by the user (available mathematical operations: addition, subtraction, multiplication, division, extract the root)

The scope of measurement of steam, water parameters and other media

- The flow and heat measurement of superheated or saturated steam or water are according to IAPWS-IF97 recommendations in the operating range of temperature 0 .. 800 ºC and absolute pressure 0.05 .. 16.52 MPa

- Flow and energy measurements of liquids other than water are performed in the range of tabular values entered by the user – density and enthalpy as function of temperature

- Measurement of technical gas flow according to the ideal gas equation

Totalizers

- Totalizers for energy and flow measurements (2 for each channel)

- Totalizers can be reset manually or automatically every day, week or month

- Over and under counters to be realized in additional channels X

Alarms and control

- 2 alarm thresholds for each result

- Alarm or control mode, signaling failure of sensors connected to analogue inputs

- 4 solid state relays rated at 0.1 A/60 V

- E-mail messages about alarm states and cyclical reports with counter values (max. 5 recipients)

Recording measurement results

- Archive files: process values (recording rate from 3 s up to 24 h), totalizers and min/average/max values (record every 1 h and every 24 h)

- Event files: authorization log file, event log file, settings log file (recording after the occurrence of the event)

- 2 recording rates, toggled by alarm state for shorting/opening time of selected binary inputs

- Access to recorded data through USB port on the front panel or through Ethernet port

- Checksum secured files – protection against data manipulation

| COMPENSATED FLOW AND HEAT ENERGY MEASUREMENT | |

| Accuracy of compensated steam, water, other liquid or technical gas flow | <2% (typowo <0,5%) |

| Frequency of measurement and calculation results | 0,5 s |

| FRONT PANEL | |

| Display type FP-70P | 5” LCD TFT colour 800x480px |

| Display type FP-70W | 7” LCD TFT colour 800x480px |

| Display size | 152mm x 91mm |

| LED indication | 3 colour LEDs |

| INPUTS ORGANIZATION | |

| FP70P, FP70W | 2 x PULS: IN1, IN2

2 x RTD: IN3, IN4 6 x I: IN5 – IN10 |

| RTD type analogue inputs | |

| Sensor type | Resistance (according to the table) |

| Measuring range | -200 .. +850 °C dla Pt100

-60 .. +150 °C dla Ni100 -180 ..+200 °C dla Cu100 |

| Sensor connection | 2, 3, or 4-wire |

| Wire resistance compensation | Manual, in range -99.99 .. +99.99 W |

| Maximum resistance of connecting wires | 20 W |

| A/D converter resolution | 24 bit |

| Accuracy (at Ta = +20 °C) | ± 0,5 °C (typowo ± 0,3 °C) |

| Temperature drift | Max ± 0,02 °C / °C |

| Galvanic isolation between inputs | No, common potential GND for all inputs |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| 0/4-20mA type analogue inputs | |

| Signal type | 0-20mA lub 4-20mA |

| Transmitter connection | Passive (supplied from measuring loop) or active converter) |

| Input resistance | 12 W ±10% ? |

| Transmitters supply | 24 VDC / max 22 mA |

| A/D converter resolution | 24 bit |

| Accuracy (at Ta = +20 °C) | ±0.1% of the range (typically ±0.05% of the range) |

| Temperature drift | Max ±50 ppm / °C |

| Galvanic isolation between inputs | No, common potential GND for all inputs |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| PULS type inputs (binary/pulse/frequency) | |

| Maximum input voltage | ±28 VDC |

| Galvanic isolation between inputs | No, common potential GND for all inputs |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| Functions | State detection

Pulse counting Frequency measurement |

| Measuring range | 0,02 Hz do 12,5 kHz |

| Minimum impulse width | 20 ms

0.5 ms with filtrating capacitor |

| Accuracy (at Ta = +20 °C) | 0.02% |

| Configuration: OC/contact(1) | |

| Open circuit voltage | 12 V |

| Short circuit current | 12 mA |

| On/off threshold | 2.7 V / 2.4 V |

| (1)The default setting. | |

| Configuration: voltage input | |

| Input resistance | >10 kW |

| On/off threshold | 2.7 V / 2.4 V |

| Open circuit voltage | 12 V |

| Configuration: Namur | |

| High impedance state | 0.4 .. 1 mA |

| Low impedance state | 2.2 .. 6.5 mA |

| 4-20mA analogue output (optional) | |

| Number of outputs | 1 or 2 |

| Output signal | 4-20mA (3.6–22 mA) |

| Maximum voltage between I+ and I- | 28 VDC |

| Loop resistance (at Ucc = 24 V) | 0 .. 500 Ω |

| Converter resolution D/A | 16 bits |

| Accuracy | 0.5% |

| Current loop supply | External or internal power supply 24 VDC / 22 mA |

| Galvanic isolation between outputs | 400 VAC (functional isolation) |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| Binary outputs (Solid State Relays) | |

| Number of outputs | 4 |

| Type of outputs | Solid State Relays |

| Maximum load current | 100 mA DC/AC |

| Maximum voltage | 60 V DC/AC |

| Galvanic isolation between outputs | 400 VAC (functional isolation) |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| RS-485 serial port | |

| Maximum load | 32 receivers/transmitters |

| Maximum line length | 1200 m |

| Maximum differential voltage A(+) – B(-) | -7 .. +12 V |

| Maximum total voltage A(+) – ‘ground’ or B(-) – ‘ground’ |

-7 .. +12 V |

| Minimal output signal from transmitter | 1.5 V (for R0 = 54 W) |

| Minimum receiver sensitivity | 200 mV / RIN = 12 kW |

| Minimum impedance of data transmission line | 54 W |

| Internal terminating resistor | Yes, activated by short-circuit pins on terminal block |

| Short-circuit/thermal protection | Yes/Yes |

| Transmission protocol | Modbus RTU |

| Baud rate | 2.4, 4.8, 9.6 ,19.2, 38.4, 57.6, 115.2 kbps |

| Parity control | Even, Odd, None |

| Frame | 1 start bit, 8 data bits, 1 stop bit |

| Galvanic isolation | No |

| Ethernet port | |

| Transmission protocol | Modbus TCP, ICMP (ping), DHCP server, http server |

| Interface | 10BaseT Ethernet |

| Data buffer | 300 B |

| Number of opened connections (simultaneously) | 4 |

| Connector type | RJ-45 |

| LED signaling | 2, build in RJ-45 socked |

| USB port | |

| Socket type | A type, according to USB standard |

| Version | USB 2.0 |

| Socket protection class | IP54 |

| Recording format | FAT16 (within a limited scope) |

| Recording indication | red-orange-green LED on the front panel |

| FP70P power supply | |

| Supply voltage | 24 VDC (15 .. 30 VDC) |

| Maximum power consumption | 14 VA / 14 W |

| FP70W power supply | |

| Supply voltage | 100 .. 240 VAC 50/60 Hz

24 VDC (15 .. 30 VDC) |

| Maximum power consumption | 28 VA / 28 W (for 100 .. 240 VAC power supply)

14 VA / 14 W (for 24 VAC/VDC power supply) |

| Wire terminals | |

| Type | · FP70P: screw type terminal blocks

· FP70W: spring type terminal block |

| Conductor cross section | · FP70P: solid max. 1.5 mm2

· FP70W: stranded 0.2 .. 1.5 mm2 |

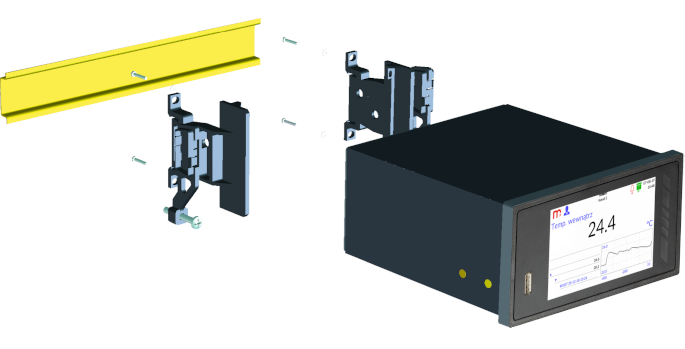

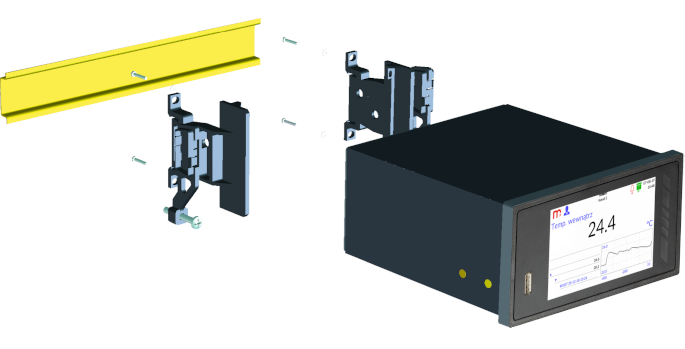

| FP70P enclosure – dimensions | |

| Enclosure type | Panel mount, nonflammable plastic material ‘Noryl’ |

| Dimensions (width x height x depth) | 192 mm x 96 mm x 63.5 mm |

| Enclosure depth with terminals | ca. 72 mm |

| Panel cut-out dimensions (width x height) | 186+1.1 mm x 92+0.6 mm |

| Panel maximum thickness | 5 mm |

| Weight | ca. 0.7 kg |

| Protection class from the front panel | IP54 |

| Protection class from the rear panel | IP30 |

| FP70W enclosure – dimensions | |

| Enclosure type | Wall mount, PC material |

| Dimensions (width x height x depth) | 257 mm x 217 mm x 125 mm (without cable glands)

257 mm x 247 mm x 125 mm (with cable glands) |

| Weight | ca. 2.1 kg |

| Protection class | IP54 |

| FP70P environmental conditions | |

| Ambient temperature | 0 .. +40 °C |

| Relative humidity | 0 .. 75% (without steam condensation) |

| Storage temperature | -20 .. +80 °C |

| Overvoltage category | OV II |

| Pollution degree | PD 2 |

| LVD (safety) | EN 61010-1 |

| EMC | Directive 2014/30/EU:

· immunity for industrial environments according to EN 61326-1:2013 (Table 2) · conductive and radiated emissions Class A equipment according to EN 61326-1:2013 |

| RoHS | Directive 2011/65/EU |

| Installation location | Indoor only |

| FP70W environmental conditions | |

| Ambient temperature | -20 .. +40 °C |

| Relative humidity | 0 .. 75% (without steam condensation) |

| Storage temperature | -20 .. +80 °C |

| Overvoltage category | OV II |

| Pollution degree | PD 2 |

| LVD (safety) | EN 61010-1 |

| EMC | Directive 2014/30/EU:

· immunity for industrial environments according to EN 61326-1:2013 (Table 2) · conductive and radiated emissions Class A equipment according to EN 61326-1:2013 |

| RoHS | Directive 2011/65/EU |

| Installation location | Indoor or outdoor(2) |

| (2)If additional protection against atmospheric precipitation is provided (roofing), the device can be installed outdoor. | |

Flow computer

- Up to 2 independent installations (A, B )

- Flows and energy balance calculations (systems X )

- 10 measurement inputs

- Math channels & functions (+, -, /, *, √)

- Alarm & control functions, 4 solid state relays (SSR)

- 4-20mA analogue output – one or two (option)

- Advanced data logging, recording data to the text files, 2 GB internal data memory

- User configurable data presentation, the colour TFT display

- RS-485 port (Modbus RTU)

- Ethernet port (Modbus TCP, www server)

- USB port on the front panel

- GSM module (option)

- Dedicated PC software for commissioning and archive data visualization

- Available languages: EN, DE, ES, FR, IT, PL, PT

Applications for steam, liquids and technical gases

- For A, B main application setup one of possible applications using a configuration wizard:

- the flow and heat of a liquid medium

- the flow and delta heat of a liquid medium in a closed supply-return installation

- the flow and delta heat of a liquid medium in an installation with different supply and return flow rates

- the flow and heat of a steam

- the flow and heat of steam for steam-condensate conditions

- the flow and delta heat in a closed steam-condensate installation

- the flow and delta heat in a steam-condensate installation with different steam and condensate flow rates

- the flow and delta heat in a steam-generating installation with the supplied water flow rate measured

- the flow and heat of a technical gases

Flow rate measurement

- The flow computer can work with:

- mass flowmeters

- volume flowmeters

- differential pressure devices with approximation by square root curve or differential pressure devices (orifices and nozzles) according to iteration algorithm according to

PN-EN ISO 5167 standard (only for water and steam)

Inputs and channels types

FP70P/FP70W has: 10 analogue inputs, Ethernet port and RS-485 port. In addition, 24 auxiliary channels are available, which can be used as measuring channels or as a math channels. The device enables supplying the current loop for 4-20mA transducers. Up to 10 User’s characteristics can be defined.

- 2 x RTD, two inputs adapted for connection of resistance temperature sensors (Pt100, Pt200, Pt500, Pt1000, Ni100, Ni120, Ni1000, Cu50, Cu53, Cu100, KTY81, KTY83, KTY84)

- 6 x I, six inputs for interaction with 0/4-20mA transducers only,

-

2 x PULS, two inputs intended for connection of transducers with a pulse output (range 0.02 Hz … 12,5 kHz).

Auxiliary channel

- 24 auxiliary channels, measurement of additional quantities or calculation of the formula entered by the user (available mathematical operations: addition, subtraction, multiplication, division, extract the root)

The scope of measurement of steam, water parameters and other media

- The flow and heat measurement of superheated or saturated steam or water are according to IAPWS-IF97 recommendations in the operating range of temperature 0 .. 800 ºC and absolute pressure 0.05 .. 16.52 MPa

- Flow and energy measurements of liquids other than water are performed in the range of tabular values entered by the user – density and enthalpy as function of temperature

- Measurement of technical gas flow according to the ideal gas equation

Totalizers

- Totalizers for energy and flow measurements (2 for each channel)

- Totalizers can be reset manually or automatically every day, week or month

- Over and under counters to be realized in additional channels X

Alarms and control

- 2 alarm thresholds for each result

- Alarm or control mode, signaling failure of sensors connected to analogue inputs

- 4 solid state relays rated at 0.1 A/60 V

- E-mail messages about alarm states and cyclical reports with counter values (max. 5 recipients)

Recording measurement results

- Archive files: process values (recording rate from 3 s up to 24 h), totalizers and min/average/max values (record every 1 h and every 24 h)

- Event files: authorization log file, event log file, settings log file (recording after the occurrence of the event)

- 2 recording rates, toggled by alarm state for shorting/opening time of selected binary inputs

- Access to recorded data through USB port on the front panel or through Ethernet port

- Checksum secured files – protection against data manipulation

| COMPENSATED FLOW AND HEAT ENERGY MEASUREMENT | |

| Accuracy of compensated steam, water, other liquid or technical gas flow | <2% (typowo <0,5%) |

| Frequency of measurement and calculation results | 0,5 s |

| FRONT PANEL | |

| Display type FP-70P | 5” LCD TFT colour 800x480px |

| Display type FP-70W | 7” LCD TFT colour 800x480px |

| Display size | 152mm x 91mm |

| LED indication | 3 colour LEDs |

| INPUTS ORGANIZATION | |

| FP70P, FP70W | 2 x PULS: IN1, IN2

2 x RTD: IN3, IN4 6 x I: IN5 – IN10 |

| RTD type analogue inputs | |

| Sensor type | Resistance (according to the table) |

| Measuring range | -200 .. +850 °C dla Pt100

-60 .. +150 °C dla Ni100 -180 ..+200 °C dla Cu100 |

| Sensor connection | 2, 3, or 4-wire |

| Wire resistance compensation | Manual, in range -99.99 .. +99.99 W |

| Maximum resistance of connecting wires | 20 W |

| A/D converter resolution | 24 bit |

| Accuracy (at Ta = +20 °C) | ± 0,5 °C (typowo ± 0,3 °C) |

| Temperature drift | Max ± 0,02 °C / °C |

| Galvanic isolation between inputs | No, common potential GND for all inputs |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| 0/4-20mA type analogue inputs | |

| Signal type | 0-20mA lub 4-20mA |

| Transmitter connection | Passive (supplied from measuring loop) or active converter) |

| Input resistance | 12 W ±10% ? |

| Transmitters supply | 24 VDC / max 22 mA |

| A/D converter resolution | 24 bit |

| Accuracy (at Ta = +20 °C) | ±0.1% of the range (typically ±0.05% of the range) |

| Temperature drift | Max ±50 ppm / °C |

| Galvanic isolation between inputs | No, common potential GND for all inputs |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| PULS type inputs (binary/pulse/frequency) | |

| Maximum input voltage | ±28 VDC |

| Galvanic isolation between inputs | No, common potential GND for all inputs |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| Functions | State detection

Pulse counting Frequency measurement |

| Measuring range | 0,02 Hz do 12,5 kHz |

| Minimum impulse width | 20 ms

0.5 ms with filtrating capacitor |

| Accuracy (at Ta = +20 °C) | 0.02% |

| Configuration: OC/contact(1) | |

| Open circuit voltage | 12 V |

| Short circuit current | 12 mA |

| On/off threshold | 2.7 V / 2.4 V |

| (1)The default setting. | |

| Configuration: voltage input | |

| Input resistance | >10 kW |

| On/off threshold | 2.7 V / 2.4 V |

| Open circuit voltage | 12 V |

| Configuration: Namur | |

| High impedance state | 0.4 .. 1 mA |

| Low impedance state | 2.2 .. 6.5 mA |

| 4-20mA analogue output (optional) | |

| Number of outputs | 1 or 2 |

| Output signal | 4-20mA (3.6–22 mA) |

| Maximum voltage between I+ and I- | 28 VDC |

| Loop resistance (at Ucc = 24 V) | 0 .. 500 Ω |

| Converter resolution D/A | 16 bits |

| Accuracy | 0.5% |

| Current loop supply | External or internal power supply 24 VDC / 22 mA |

| Galvanic isolation between outputs | 400 VAC (functional isolation) |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| Binary outputs (Solid State Relays) | |

| Number of outputs | 4 |

| Type of outputs | Solid State Relays |

| Maximum load current | 100 mA DC/AC |

| Maximum voltage | 60 V DC/AC |

| Galvanic isolation between outputs | 400 VAC (functional isolation) |

| Galvanic isolation from supply voltage | 400 VAC (functional isolation) |

| RS-485 serial port | |

| Maximum load | 32 receivers/transmitters |

| Maximum line length | 1200 m |

| Maximum differential voltage A(+) – B(-) | -7 .. +12 V |

| Maximum total voltage A(+) – ‘ground’ or B(-) – ‘ground’ |

-7 .. +12 V |

| Minimal output signal from transmitter | 1.5 V (for R0 = 54 W) |

| Minimum receiver sensitivity | 200 mV / RIN = 12 kW |

| Minimum impedance of data transmission line | 54 W |

| Internal terminating resistor | Yes, activated by short-circuit pins on terminal block |

| Short-circuit/thermal protection | Yes/Yes |

| Transmission protocol | Modbus RTU |

| Baud rate | 2.4, 4.8, 9.6 ,19.2, 38.4, 57.6, 115.2 kbps |

| Parity control | Even, Odd, None |

| Frame | 1 start bit, 8 data bits, 1 stop bit |

| Galvanic isolation | No |

| Ethernet port | |

| Transmission protocol | Modbus TCP, ICMP (ping), DHCP server, http server |

| Interface | 10BaseT Ethernet |

| Data buffer | 300 B |

| Number of opened connections (simultaneously) | 4 |

| Connector type | RJ-45 |

| LED signaling | 2, build in RJ-45 socked |

| USB port | |

| Socket type | A type, according to USB standard |

| Version | USB 2.0 |

| Socket protection class | IP54 |

| Recording format | FAT16 (within a limited scope) |

| Recording indication | red-orange-green LED on the front panel |

| FP70P power supply | |

| Supply voltage | 24 VDC (15 .. 30 VDC) |

| Maximum power consumption | 14 VA / 14 W |

| FP70W power supply | |

| Supply voltage | 100 .. 240 VAC 50/60 Hz

24 VDC (15 .. 30 VDC) |

| Maximum power consumption | 28 VA / 28 W (for 100 .. 240 VAC power supply)

14 VA / 14 W (for 24 VAC/VDC power supply) |

| Wire terminals | |

| Type | · FP70P: screw type terminal blocks

· FP70W: spring type terminal block |

| Conductor cross section | · FP70P: solid max. 1.5 mm2

· FP70W: stranded 0.2 .. 1.5 mm2 |

| FP70P enclosure – dimensions | |

| Enclosure type | Panel mount, nonflammable plastic material ‘Noryl’ |

| Dimensions (width x height x depth) | 192 mm x 96 mm x 63.5 mm |

| Enclosure depth with terminals | ca. 72 mm |

| Panel cut-out dimensions (width x height) | 186+1.1 mm x 92+0.6 mm |

| Panel maximum thickness | 5 mm |

| Weight | ca. 0.7 kg |

| Protection class from the front panel | IP54 |

| Protection class from the rear panel | IP30 |

| FP70W enclosure – dimensions | |

| Enclosure type | Wall mount, PC material |

| Dimensions (width x height x depth) | 257 mm x 217 mm x 125 mm (without cable glands)

257 mm x 247 mm x 125 mm (with cable glands) |

| Weight | ca. 2.1 kg |

| Protection class | IP54 |

| FP70P environmental conditions | |

| Ambient temperature | 0 .. +40 °C |

| Relative humidity | 0 .. 75% (without steam condensation) |

| Storage temperature | -20 .. +80 °C |

| Overvoltage category | OV II |

| Pollution degree | PD 2 |

| LVD (safety) | EN 61010-1 |

| EMC | Directive 2014/30/EU:

· immunity for industrial environments according to EN 61326-1:2013 (Table 2) · conductive and radiated emissions Class A equipment according to EN 61326-1:2013 |

| RoHS | Directive 2011/65/EU |

| Installation location | Indoor only |

| FP70W environmental conditions | |

| Ambient temperature | -20 .. +40 °C |

| Relative humidity | 0 .. 75% (without steam condensation) |

| Storage temperature | -20 .. +80 °C |

| Overvoltage category | OV II |

| Pollution degree | PD 2 |

| LVD (safety) | EN 61010-1 |

| EMC | Directive 2014/30/EU:

· immunity for industrial environments according to EN 61326-1:2013 (Table 2) · conductive and radiated emissions Class A equipment according to EN 61326-1:2013 |

| RoHS | Directive 2011/65/EU |

| Installation location | Indoor or outdoor(2) |

| (2)If additional protection against atmospheric precipitation is provided (roofing), the device can be installed outdoor. | |